Society of St. Francis Xavier, Pilar’s Fr. Conceicao Rodrigues College of Engineering

Society of St. Francis Xavier, Pilar’s

Society of St. Francis Xavier, Pilar’s

Fr. Conceicao Rodrigues College of Engineering

| An Autonomous Institute Affiliated to University of Mumbai | NAAC "A" Grade Accredited |

Mechanical Enginnering

Turning ideas into physical reality through design, analysis, and innovation.

About

- B.Tech with Multidisciplinary Minor

- B.Tech with Double Minor (Multidisciplinary & Specialization Minor)

- B.Tech with Research and Multidisciplinary Minor

- Ph.D (Doctorate) in Mechanical Engineering

Vision and Mission

Building a comprehensive academic and research ecosystem for transforming young minds into qualified innovative mechanical engineers with human values.

Impart quality education through state-of-art facilities and effective teaching-learning process.

Collaborate with educational institutions, industries, and professional societies.

Promote the culture of ethical research for developing self-sustainable engineers competent for entrepreneurship and higher studies.

PEOs, POs and PSOs

- To prepare the stake holder to exhibit leadership qualities with demonstrable attributes in lifelong learning to contribute to the societal needs.

- To make ready the stake holder to pursue higher education for professional development

- To help the stake holder to acquire the analytical and technical skills, knowledge, analytical ability attitude and behavior through the program

- To prepare the stakeholders with a sound foundation in the mathematical, scientific and engineering fundamentals

- To motivate the learner in the art of self-learning and to use modern tools for solving real life problems and also inculcate a professional and ethical attitude and good leadership qualities.

- To prepare the stake holder to able to Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

Engineering Graduates will be able to

- Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/Development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for public health and safety, and the cultural, societal, and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis, and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling of complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and the need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and teamwork: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project Management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-long learning: Recognized the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Student will have the ability to

- To apply modern learning tools and computational methods for simulating real-life mechanical engineering problems and manufacturing systems to predict the response, system behaviour and optimize the solutions.

- To acquire and implement the knowledge of advanced manufacturing technologies as per the changing industrial needs and build a sense of teamwork to work on industrial projects and pursue higher education to contribute in the research and development.

PEOs, POs and PSOs

- To prepare the stake holder to exhibit leadership qualities with demonstrable attributes in lifelong learning to contribute to the societal needs.

- To make ready the stake holder to pursue higher education for professional development

- To help the stake holder to acquire the analytical and technical skills, knowledge, analytical ability attitude and behavior through the program

- To prepare the stakeholders with a sound foundation in the mathematical, scientific and engineering fundamentals

- To motivate the learner in the art of self-learning and to use modern tools for solving real life problems and also inculcate a professional and ethical attitude and good leadership qualities.

- To prepare the stake holder to able to Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

Engineering Graduates will be able to

- Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/Development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for public health and safety, and the cultural, societal, and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis, and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling of complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and the need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and teamwork: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project Management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-long learning: Recognized the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Student will have the ability to

- To apply modern learning tools and computational methods for simulating real-life mechanical engineering problems and manufacturing systems to predict the response, system behaviour and optimize the solutions.

- To acquire and implement the knowledge of advanced manufacturing technologies as per the changing industrial needs and build a sense of teamwork to work on industrial projects and pursue higher education to contribute in the research and development.

Faculty Members

Supporting Staff

Lab Assistant

Deepak Gaikwad

Fitting Instructor

Xavier D'Souza

Lab. Assistant

Santosh Dharman

Placement Data

List of Students

Infrastructure

Mechanisms and Machines Laboratory

It facilitates experimentation related to mechanics with Force Table Apparatus, Coil & Belt Friction Apparatus, Friction Slide Apparatus, Simple Beam Apparatus, Collision of Elastic Bodies Apparatus, Bell Crank Lever, Friction Slide Apparatus as well as experimentation related to dynamics of machines with static & dynamic balancing apparatus, Whirling Speed of shaft, Gyroscope, Governor, Cam analysis apparatus, Coriolis Component of acceleration, Piezoelectric Vibrometer and Vibration Apparatus.

CAD/CAM laboratory

It is well-equipped with state-of-art computational facilities including High-End Graphic Workstations with 3D Modeling and Analysis Softwares such as Ansys, NX11, Solidworks, Autocad, 3D Printer.

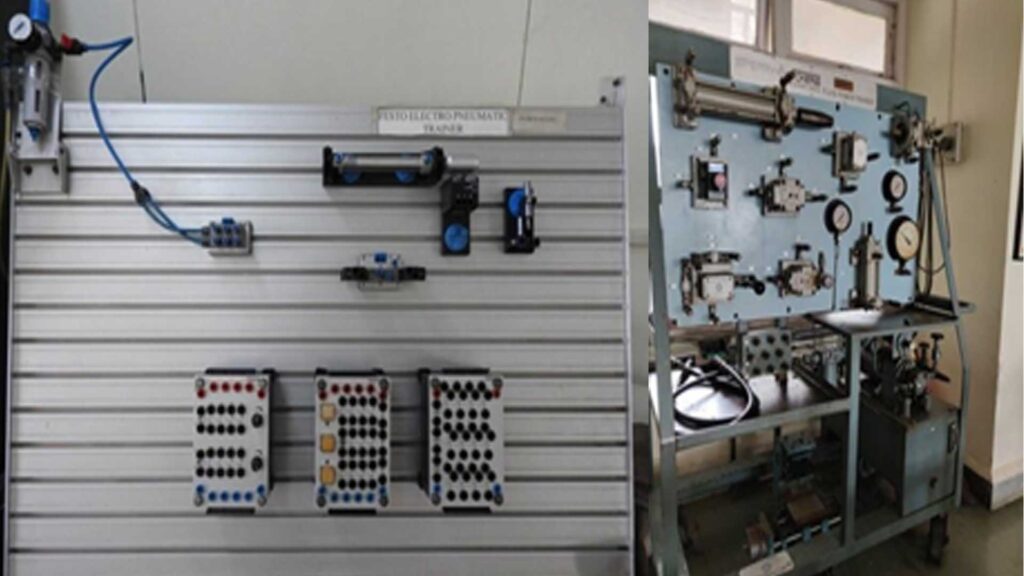

Automation and Control laboratory

It includes automation and control equipments such as Festo Pneumatic and Electro-Pneumatic Trainers, PCS Trainers, Fluidsim.

Manufacturing Systems & Management / IE laboratory

It facilitates analysis of industrial engineering and operations management problems with Arena Manufacturing System Analysis Software and MATLAB

Metrology and Quality Engineering laboratory

It is equipped with high precision metrology instruments such as Vickers Hardness Tester, Profile Projector, Surface Plate, Vernier Caliper, Outside Micrometer, Inside Micrometer, Vernier Height Gauge, Dial Test Indicator, Slip Gauges, Mechanical Comparator, Monochromatic Check Light Unit, Optical Flat and Specimen, Gear Tooth Vernier, Sine Bar

HVAC laboratory

It facilitates experimentation related to HVAC using cooling tower, Ice plant, open type air conditioning test rig and vapour absorption refrigeration test rig.

Turbo Machinery laboratory

It facilitates experimentation related to Tourbo Machinery using Pelton Turbine, Francis Turbine, Venturimeter, Impact of Jet Apparatus, Air compressor, Metacentric Height and Bernoulli’s Apparatus.

Machine Shop

Machine shop is equipped with adequate Conventional Lathes, Shaper, Milling Machine, Drilling Machine, Grinder, Universal Milling Machine (Deckle) Along With Modern Production Grade CNC Turning and Milling Machines.

PG Laboratory (Project Based Learning)

It provides an environment for projects based learning and is equipped with Modelling Softwares, MATLAB and other Statistical Analysis Freewares.

Materials and Materials Testing Laboratory

This lab facilitates experimentation related to Materials Testing. It is equipped with Universal Testing Machine (UTM), Impact Testing Equipment, Fatigue Testing Machine, Muffle Furnace, Inverted Metallurgical Microscope, Jominy End Quench Test Equipment, Disc Polishing Machining, Oil Quenching Tank, Desiccator, and Hardness Tester.

Highlights

The institute has established placement services and our students are placed by reputed recruiters like Larsen &Toubro, Godrej and Boyce, Siemens, Mahindra and Mahindra, Mercedes Benz, General Mills, Accenture, Tata Consultancy Services, Capgemini Technologies, Cognizant Technologies, Nerolac Kansai, Argon & Co., Reliance Retail, Mazgaon Dock etc.

Our students are welcomed in various reputed national institutes and international universities in USA and UK. In the past, students have got admitted to reputed universities abroad like Cornell USA, Georgia Tech USA, Harvard USA, Delft Netherlands, KTH Sweden.

SAE (Society of Automotive Engineers) – CRCE

SAE-CRCE is the prestigious student chapter of SAE-INDIA. SAE project teams participate every year and win commendable positions in National / International competitions like SAE Baja, SAE Aero-design and Formula Bharat. Workshops, seminars and industrial visits in association with some top automobile companies like Voltas, Toyota, Tata Motors, etc are regularly organized by the chapter.

ASME (The American Society Of Mechanical Engineers)

American Society of Mechanical Engineers is one of the international Technical councils of CRCE and the only International council of Mechanical and Production Department. It enables collaboration, knowledge sharing, career enrichment and skill development with a mission to promote and enhance the technical competency and professional well-being of our members.

IIIExCRCE (The Indian Institution of Industrial Engineering)-CRCE

This chapter aims to bridge the gap between industry and academia for Mechanical and Production engineering students through expert workshops and industrial visits. IIIExCRCE won the ‘Best Student Chapter’ award at NHQ, Belapur and the faculty incharges and students were also felicitated with excellence award trophies by IIIE Mumbai Chapter who organized a prize distribution ceremony on October 2, 2021 to congratulate and appreciate the various student sections of IIIE for their exemplary work

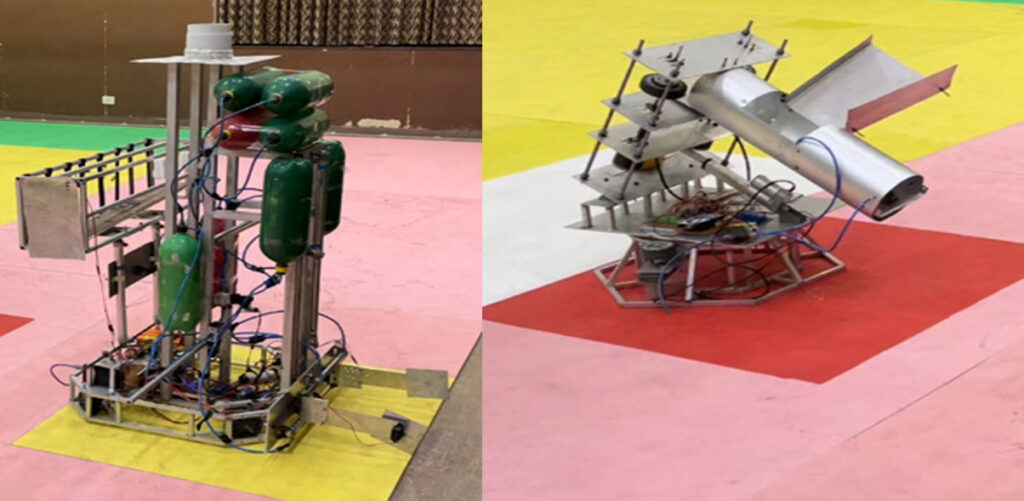

Team ABADHA

Team ABADHA produces All Terrain Vehicle from buggy making to final ATV overcoming all constraints of time, investments, social connect activities etc. all under one roof in campus of Fr.CRCE and participates in the National Level competitions like SAE BAJA. They participated in Virtual E-BAJA SAE INDIA 2021-22 competition with flying colors. Team Abadha secured an overall rank of 15 at E-Baja SAE India Competition in June 2022 held at Pithampur, Indore, on the tracks of NATRAX and proved an exciting experience for students.

Team CRCE Formula Racing

Team CRCE Formula Racing (CFR) fabricated Formula Racing Car and participated in Formula Bharat 2022 competition and received best-ever overall rank of 12th. They are presently working on Electric Vehicle for 2023 competitions.

Team Robocon

The Team is preparing to participate in Flipkart’s Flagship Engineering Campus Challenge 2021 and Robocon-2022. Team Robocon CRCE, participated in the national-level Brainwreck competition, organized by Invictus Robotics Club of MIT Academy of Engineering in the year 2020-2021 and emerged as national winners with All India Rank 1. Also they received the Best Circuit Design Award among the 90 teams that participated in this event. Team Robocon secured an overall rank of 21 at ABU Robocon competition organised by IIT Delhi.

Team Vaayushastra

Team Vaayushastra secured 5th rank globally at Advanced Class SAE Aero Design West competition in April 2021. The objective for In the academic year 2021-2022 the objective was to design a suite of systems that can support the fight against wildfires through the delivery of water and parts for a ground vehicle. Ground Transport Vehicle (GTV) was safely to be delivered to the ground through a powered and autonomously guided aircraft PADA. Due to the global pandemic, team could only participate in design report and presentation rounds in which it was able to secure 4th rank and 6th rank respectively, and 5th rank globally.

The department provides a variety of seminars, workshops, guest lectures, student / faculty development programmes, and industrial visits to help students obtain technical knowledge and skills while also introducing them to the industrial environment.

Institute has facilities to conduct research in following mechanical engineering areas

- Open Architecture CNC machines

- Minimum Quantity Lubrication

- Vision based measurement systems

- Manufacturing systems analysis

- Rapid prototyping of injection moulds

- Advanced casting methods

- Materials analysis and testing

- Product design

- High speed machining

- CNC machining

- Advanced machining and manufacturing methods

- CAD/CAM

- Computational methods in flow analysis

- Automation and control

- Automobiles and aerospace

- Electric Vehicles

- Composites

- Thermals and Fluids

- Industrial Engineering

Institute offers various mechanical engineering related short term certificate courses in computer aided design and manufacturing simulation using NX11, computer aided design using Solidworks, CNC Turning and Milling (Operations and Programming) and Manufacturing systems analysis using ARENA.

Research

Publications

Publications for the year 2024-25

1. Sonia M. Pol, Bhushan T. Patil, Amit Lopes (2025). Revelation Through Principal Component Analysis: Enhancing Decision-Making in Injection Molding Process Parameters Using Simulation Data and Computer-Aided Engineering. 9th International Conference on Information and Communication Technology for Intelligent Systems, Bangkok, Thailand held during April 04–06, 2025 at Bangkok, Thailand

2. Sonia M. Pol, Bhushan T. Patil, Amit Lopes (2025). Optimizing Injection Molding Process Parameters Using Artificial Intelligence-Based K-Means Clustering: A Simulation Data and Computer-Aided Engineering Approach. 9th International Conference on Information and Communication Technology for Intelligent Systems, Bangkok, Thailand held during April 04–06, 2025 at Bangkok,Thailand

3. Sonia M. Pol, Bhushan T. Patil, Amit Lopes (2025). Investigation of the Impact of Injection Molding Parameters on Defects Using One-Way ANOVA: Analysis of Data Acquired through Computer-Aided Engineering. International Conference on Materials Science and Manufacturing Technology (ICMSMT 2025).

4. Meera Kokate, Sonia M. Pol, Bhushan T. Patil, Ketaki N. Joshi, and Amit J. Lopes (2025). Prediction of Residual Stresses in Injection Moulded Helmet Visor using Computer Aided Engineering and Artificial Neural Network (ANN). International Conference on Materials Science and Manufacturing Technology (ICMSMT 2025).

5. Sonia M. Pol, Shaunak A. Aital, Ayushi Khatri, Bhushan T. Patil, and Amit J Lopes (2025). Risk analysis in Healthcare Industry: Leveraging Monte Carlo, Markov chains and Preference Matrix Models. 2nd International Conference on Technologies for Energy, Agriculture, and Healthcare (ICTEAH 2025)

6. Sonia M. Pol, Shaunak A. Aital, Bhushan T. Patil, and Amit J Lopes (2025). Markov Chain Simulation for Pharmaceutical Medicine Inventory Optimization amidst Pandemic Conditions: Analysing ABC And VED Inventory Policies. 2nd International Conference on Technologies for Energy, Agriculture, and Healthcare (ICTEAH 2025)

7. Onkar Potadar, Bhushan T. Patil (2025). Sentiment Analysis of Linkedin Reviews on National Education Policy-NEP2020. National Conference on National Education Policy a Paradigm Shift & Implications on Online Education organized by D Y Patil Vidyapeeth Pune held on 27-28 September 2024

8. Sonia M. Pol, Bhushan T. Patil, Ketaki Joshi, Amit Lopes (2024). Selection of Additive Manufacturing Technique by Using Multi Criteria Decision Making Methodology Viz. Analytical Hierarchy Process, Fifth International Conference on Advances in Physical Sciences and Materials (ICAPSM) held at Builders Engineering College, Kangeyam, Tamil Nadu,India During 29-30,August 2024

9. Yashraj Pandit, Musavvir Hanure, Vedika Vartak, Dipali Bhise (2025). Comparative Analysis of Lithium-ION Arrangement Pattern using CFD, International conference on sustainable industry 4.0: innovations for a greener future, organised by D Y Patil Institute of Technology, Pune, 11th and 12th April 2025

10. Vaidehi Kokare, Dipali Bhise (2025). Evaluation of Viscocity Models for Simulation of Airfoil Analysis, 3rd ICMEESD-2025 organised by SKNSCOE , 29 March 2025

11. M V B Rao, S S Rathod (2025). Aligning Ocean Conservation with SDG: Managing Waste Along Mumbai’s Coastline in India, Inter. Conf. on Climate Change (ICCC2025), Chandrapur, Book-I, pp. 201-205, 16-18 Jan 2025 (ISBN-978-93- 48606-60-0).

12. Siddhi More, Sonia M. Pol, Dnyaneshwari Shinde, Sameeksha Naik, Bhushan T. Patil. (2024), Experimentation in Injection Molding: Simulation and Parameter Optimization Using Design of Experiment (2024) Fifth International Conference on Advances in Physical Sciences and Materials (ICAPSM) , held at Builders Engineering College, Kangeyam, Tamil Nadu, India During 29-30,August 2024)

Publications for the year 2023-24

1. Bhise, D. K., Patil, B. T., Shaikh, V. A., and Deshmukh, S. P. (2024). Comparative Economic Analysis and Investigation of Micro Lubrication Over Conventional Cooling in Manufacturing. Journal of Engineering, Project, and Production Management, 14(1), 0004. http://doi.org/10.32738/JEPPM-2024-0004

2. Miriyala, V., Patil, B. T., Shaikh, V. A., Sudhakar, D. S. S., and Deshmukh, S. (2024). Investigations of Surface Roughness and Temperatures in Vegetable Oil-based n- MQL Turning of AISI 4340 Steel. Journal of Engineering, Project, and Production Management, 14(1), 0003. http://doi.org/10.32738/JEPPM-2024-0003

3. Pol Sonia M , Aniket Rayte, Bhushan T Patil, Ketaki N Joshi (2024). Analysis and Optimization of Transportation Logistics for Supply Chain Management of Perishable Goods using Monte Carlo Simulation, 2024 International Conference on Sustainable Technologies in Civil and Environmental Engineering (ICSTCE 2024) E3S Web of Conf., 559 (2024) 04004 held at Dr. D.Y. Patil Institute of Technology, Pimpri, Pune, Maharashtra, India during 06 – 07, June 2024.

4. Sonia Pol, Shaunak Aital, Siddhi More, Dr. Hemant Khanolkar, Bhushan Patil (2024) Experimentation and analysis of Industrial Chimneys and solar chimney power plant: A comprehensive literature review, International Conference on Materials Science and Manufacturing Technology (ICMSMT 2024) held during 03 – 04, May 2024 at Akshaya College of Engineering and Technology, Coimbatore, Tamil Nadu, India during 03 – 04, May 2024.

5. Janhavi Sachin Shinde, Shubham Dinesh Sawant, Jaydenmario Joseph Fernandes, Aayush Devendra Patil, Dr. Bhushan T. Patil, Sonia Pol, Dr. Hemant Khanolkar (2024). Electrochemical Additive Manufacturing: A Comprehensive Literature Review, 2024 International Conference on Materials Science and Manufacturing Technology (ICMSMT 2024) held during 03 – 04, May 2024 at Akshaya College of Engineering and Technology, Coimbatore, Tamil Nadu, India during 03 – 04, May 2024.

6. Hardik Karpe, Ketaki Joshi, Bhushan T. Patil (2024). A Comparative Analysis and Predictive Modelling of AA5754-O and AA6061-O in Single Action Sheet Metal Forming for Automotive Structural B-Pillar, Sixth International Conference on Materials Science and Manufacturing Technology (ICMSMT 2024) during 03 – 04, May 2024 at Akshaya College of Engineering and Technology, Coimbatore, Tamil Nadu, India.

Publications for the year 2022-23

1. Miriyala, V., Patil, B. T., Shaikh, V. A., Sudhakar, D. S. S., and Deshmukh, S. (2023). Investigations of Surface Roughness and Temperatures in Vegetable Oil-based n-MQL Turning of AISI 4340 Steel. Journal of Engineering, Project, and Production Management, 14(1), 0003. DOI: 10.32738/JEPPM-2024-0003

2. Bhise, D. K., Patil, B. T., Shaikh, V. A., and Deshmukh, S. P. (2023). Comparative Economic Analysis and Investigation of Micro Lubrication Over Conventional Cooling in Manufacturing. Journal of Engineering, Project, and Production Management, 14(1), 0004. DOI: 10.32738/JEPPM-2024-0004

3. Dohale, V., Ambilkar, P., Gunasekaran, A., & Bilolikar, V. (2022). Examining the barriers to operationalization of humanitarian supply chains: lessons learned from COVID-19 crisis. Annals of Operations Research, 1-40. DOI: 1007/s10479-022-04752-x

4. Deshmukh Sujata, Patil Bhushan, Joshi Ketaki et al. (2022). A novel method for IOT based smart traffic system. Industrial Engineering Journal, Vol. XV Issue 06 11-16

5. Korgaonkar Saurabh (2022). Literature Review on Virtual Construct of Digital Twin, MCT RGIT’s International Conference on Embracing 4.0 Technologies for Sustainable Growth (ICEI 4.0)

Publications for the year 2021-22

1. Singh, Deepika S, Patil, B.T. and Joshi, K.N. (2021). Comparative Economic Analysis of Injection-Moulded Component with Conventional and Conformal Cooling Channels, Journal of The Institution of Engineers (India): Series C, 1-11. (Scopus Indexed) DOI: https://doi.org/10.1007/s40032-021-00778-5

2. Joshi, K., & Patil, B.T. (2022). Automated inspection of spur gears using machine vision approach. International Journal of Computational Vision and Robotics (In press) (Scopus Indexed) DOI: https://doi.org/10.1504/IJCVR.2022.10044716

3. Subramanian, G., Patil, B.T. and Gardas, B.B. (2021). Evaluation of enablers of cloud technology to boost industry 4.0 adoption in the manufacturing micro, small and medium enterprises, Journal of Modelling in Management, Vol. 16 No. 3, pp. 944-962. (Scopus Indexed) DOI: https://doi.org/10.1108/JM2-08-2020-0207

4. Arun Rane (2021). Value Stream Mapping and Process Simulation for Lean Manufacturing of Circuit Breaker Line. Advance Management Science, 10(1): 19-29

5. Saurabh K (2022), Literature Review on Virtual Construct of Digital Twin, MCT RGIT’s International Conference on Embracing 4.0 Technologies for Sustainable Growth (ICEI 4.0)

6. MVB Rao, Bhushan Patil, Vasim Shaikh, DSS Sudhakar, Sujata Deshmukh (April 2022), ” Investigation of Surface Roughness and Cutting Temperature Parameters in Turning AISI 4340 Steel using MQL, Mist Technique with Nano-Fluids (n-AL2O3, n- MOS2 and n-Graphene) mixed in Edible Vegetable Coconut Oils”, MCT RGIT’s International Conference on Embracing 4.0 Technologies for Sustainable Growth (ICEI 4.0)

7. Dipali bhise, Bhushan Patil, Vasim Shaikh, Sujata Deshmukh, (April 2022), “Comparative Economic Analysis and investigation of Micro Lubrication over Conventional Cooling in Manufacturing”, MCT RGIT’s International Conference on Embracing 4.0 Technologies for Sustainable Growth (ICEI 4.0)

8. Swarangi Kale, Ddhairya Gandhi, Aditya Raj, Yashas Joglekar, Dr. Bhushan Patil, “Injection moulding process parameters and defects: A Literature review”, International Conference on embracing industry 4.0 technologies for sustainable growth (ICEI 4.0), Rajiv Gandhi Institute of Technology, Mumbai. 22nd April.

9. Khatu, R. D., Patil, B. T., Bhise, D. K., & Vaishnav, H. B. (2022). Design of a fixture for wire-cut EDM: A generic approach. Materials Today: Proceedings, 49, 2034-2041. (Scopus Indexed)

10. Advait C Purav, Deepika S Singraur and D S S Sudhakar (2021). Investigations into performance of conventional and conformal cooling channels of a plastic injection mold, IOP Conference Series Materials Science and Engineering 1070(1):012122 (Scopus Indexed)

11. S G Dubey, D S S Sudhakar and S Saha (2021), Airflow noise reduction in digital stethoscope add-on device, IOP Conf. Ser.: Mater. Sci. Eng. 1070 012109 (Scopus Indexed)

12. J. Beno, M. V. Rao, J. Beno and S. K. Das (2021). Process Control & Inspection using 5s Method and Computation with Pareto Analysis, 2021 International Conference on Advances in Computing, Communication, and Control (ICAC3), 2021, pp. 1-5, doi: 10.1109/ICAC353642.2021.9697131.

13. Jerin Beno, M VeeraBhadra Rao and Sunil Kumar Das (2021). Studies and Practice of Geometrical Test Procedures & Reconditioning of CNC Lathe Machine Tool, 2021 J. Phys.: Conf. Ser. 2070 012228

14. A. Pinto and S. Fernandes (2021). EPT (Electrically Propelled Tricycle),” 2021 International Conference on Advances in Computing, Communication, and Control (ICAC3), 2021, pp. 1-7.

15. Dohale, V., Ambilkar, P., Gunasekaran, A., & Bilolikar, V. (2022). Examining the barriers to operationalization of humanitarian supply chains: lessons learned from COVID-19 crisis. Annals of Operations Research, 1-40.

Publications for the year 2020-21

1. Joshi, K., & Patil, B. T. (2022). Multivariate statistical process monitoring and control of machining process using principal component-based Hotelling T2 charts: a machine vision approach. International Journal of Productivity and Quality Management, 35(1), 40-56. (Scopus Indexed) DOI: https://doi.org/10.1504/IJPQM.2020.10034309

2. Arun Rane (2020). Low-cost CNC Machine by Using Microcontroller. Open Journal of Mechanical Engineering, 5(1): 01-04.

3. Arun Rane (2020). Simulation of A Manufacturing System to Improve Business. Advances In Industrial Engineering And Management, 9(2): 27-32.

4. Singraur, D. S., Patil, B. T., & Shaikh, V. A. (2021). Defect Minimization of an Injection Molded Plastic Component Using Conformal Cooling Channels. In Materials Science Forum (Vol. 1019, pp. 205-210). Trans Tech Publications Ltd. DOI: https://doi.org/10.4028/www.scientific.net/MSF.1019.205

5. Bhise, D. K., Patil, B. T., & Shaikh, V. A. (2021). Air Assisted Atomization Characterization of Biodegradable Fluid Using Microlubrication Technique. In Materials Science Forum (Vol. 1019, pp. 211-217). Trans Tech Publications Ltd. DOI: https://doi.org/10.4028/www.scientific.net/MSF.1019.211

6. Veerabhadrarao, M., Patil, B. T., Shaikh, V. A., & Sudhakar, D. S. S. (2021). Contribution of Factors such as Machining Parameters, MQL Nozzle Orientation (Angle & Distance) and MQL Nano-Fluid Type on Surface Finish of Turned Steel Work-Pieces Using DOE Approach. In Materials Science Forum (Vol. 1019, pp. 181- 193). Trans Tech Publications Ltd. DOI: https://doi.org/10.4028/www.scientific.net/MSF.1019.181

7. Joshi, K., & Patil, B. (2020). Measurement of Spur Gear Parameters Using Machine Vision. In Proceedings of International Conference on Intelligent Manufacturing and Automation (pp. 31-37). Springer, Singapore. (Scopus Indexed)

8. Meera B. Kokate., Bhushan T. Patil, & Geetha Subramanian (2020). Machine Learning as a Smart Manufacturing Tool. In Proceedings of International Conference on Intelligent Manufacturing and Automation (pp. 359-366). Springer, Singapore. (Scopus Indexed)

9. Dabreo, P. W., Joshi, K. N., Patil, B. T., & Kokate, M. B. (2020, June). Machine vision based interferometry for measurement of flatness error in micro and nano manufacturing. In IOP Conference Series: Materials Science and Engineering (Vol. 872, No. 1, p. 012066). IOP Publishing. DOI: 10.1088/1757-899X/872/1/012066 (Scopus Indexed)

10. Pashte, S., Wagle, K., Agrawal, S., Sudhakar, D.S.S., Patil, B. and Singraur, D.S., 2020, June. Simulation and optimization for a plastic component. In IOP Conference Series: Materials Science and Engineering (Vol. 872, No. 1, p. 012072). DOI:10.1088/1757- 899X/872/1/012072 (Scopus Indexed)

11. Sikdar, H. N., Rao, M. V., Patil, B. T., Shaikh, V. A., & Sudhakar, D. S. S. (2020, June). Turned AISI 4340 Heat-Treated Steel Surface Quality Investigations in Dry and MQL Cooling Conditions. In IOP Conference Series: Materials Science and Engineering (Vol. 872, No. 1, p. 012090). IOP Publishing. (Scopus Indexed)

12. Suryawanshi, A. T., Sudhakar, D. S. S., & Patil, B. T. (2020, June). Low cost and open source software-based CNC router for machining contours. In IOP Conference Series: Materials Science and Engineering (Vol. 872, No. 1, p. 012084). IOP Publishing. (Scopus Indexed)

13. Bhopi, S. C., Miriyala, V. B. R., Parab, S. V., Haldankar, A. S., & Pandey, S. P. (2020, June). Study on rectification of issues faced by ultrasonic welding of medical “estethoscope” by adhesive bonding technique. In IOP Conference Series: Materials Science and Engineering (Vol. 872, No. 1, p. 012088). IOP Publishing. (Scopus Indexed)

14. Mehta, K. M., Pandey, S. K., & Shaikh, V. A. (2021). Unconventional Machining of ceramic matrix Composites–A review. Materials Today: Proceedings, 46, 7661-7669.

15. Bukane, S., Shaikh, V. A., & VeeraBhadraRao, M. (2020, December). Identifying optimization methods using MQL and Cryo-treatments for turning inconel alloy with nanofluids. In Journal of Physics: Conference Series (Vol. 1706, No. 1, p. 012219). IOP Publishing.

16. Shaikh, S., Shaikh, V. A., Rao, M. V., & Patil, B. T. (2021, February). A105 Work- Material Turning Experimentation using L9 Orthogonal Array Runs with Dry, MQL and Nano-Al2O3 Assisted MQL Machining Conditions. In IOP Conference Series: Materials Science and Engineering (Vol. 1070, No. 1, p. 012131). IOP Publishing.

17. Ambilkar, P., Dohale, V., Gunasekaran, A., & Bilolikar, V. (2021). Product returns management: a comprehensive review and future research agenda. International Journal of Production Research, 1-25. DOI: https://doi.org/10.1080/00207543.2021.1933645

Publications for the year 2019-20

1. Joshi K.N., Patil B. T.(2020), Performance Evaluation of Various Texture Analysis Techniques for Machine Vision based Characterization of Machined Surfaces, International Journal of Computational Vision and Robotics (IJCVR) (Inderscience Publications)(Scopus Indexed) DOI: https://doi.org/10.1504/IJCVR.2020.10029036

2. Joshi K. N., Patil B. T., Vaishnav H. B., (2019) Multivariate Statistical Process Monitoring: A Perspective of Machine Vision, Udyog Pragati, NITIE

3. Shaikh, V. A., and Boubekri, N., (2020), Using Vegetable-oil based Sustainable Metal Working Fluids to promote Green Manufacturing, International Journal of Manufacturing, Materials and Mechanical Engineering (IJMMME), Vol: 1, No. 1 ISSN: 2156-1680 (Scopus Indexed) DOI: https://doi.org/10.4018/IJMMME.2020010101

4. Arun Bhiva Rane (2019). Enhancement of Productivity By Eliminating Back

Chipping. Open Journal of Mechanical Engineering, 4(2): 01-05.

5. Singh D. S., Patil B. T., Shaikh, V. A., (2020) “Plastic injection molded door

handle cooling time reduction investigation using conformal cooling channels.”, Materials Today: Proceedings. First International Conference on Recent Advances in Materials and Manufacturing ICRAMM, Sept 2019, Belagavi, 27, 519-523.

6. Bhise D. K., Patil B. T., Shaikh, V. A., (2020) “Investigating the Microlubrication Flow Inside The Nozzle using Computational Fluid Dynamics”, Materials Today: Proceedings. First International Conference on Recent Advances in Materials and Manufacturing ICRAMM, Sept 2019, Belagavi, India. Elsevier Publications, 27, 492-496.

7. Rao, M. V. B., Patil, B. T., Shaikh, V. A., Sudhakar, D. S. S., (2019) “Recent Studies of Al2O3, Graphene and MoS2 Nano-Materials in Metal Working Fluids for Turning Steel – A Review”, First International Conference on Recent Advances in Materials and Manufacturing ICRAMM, Sept 2019, Belagavi, India.

8. Kawade, P, Vaishnav, H. B., Joshi, K. N., (2019) “Finite Element Simulation of Milling Process with Cryogenic Precooling of Workpiece”, First International Conference on Recent Advances in Materials and Manufacturing ICRAMM, Sept 2019, Belagavi, India.

9. Deshmukh, S. P., Deshmukh, P. D., Patil, B. T., & Thampi, G. T. (2019). Exploring the factors to make e-commerce and m-commerce ubiquitous and pervasive to improve national productivity of India. International Journal of Productivity and Quality Management, 28(4), 457-496. DOI : https://doi.org/10.1504/IJPQM.2019.103691 (Scopus Indexed)

10.Joshi K. N. and Patil B. T., (2020). Prediction of Surface Roughness by Machine Vision using Principal Components based Regression Analysis. In International Conference on Computational Intelligence and Data Science (ICCIDS 2019),167, 382-391. Elsevier(Scopus indexed)

11. Joshi K.N., Patil B.T., Vaishnav H.B. (2020) Principal Components Based Multivariate Statistical Process Monitoring of Machining Process Using Machine Vision Approach. In: Patnaik S. (eds) New Paradigm of Industry 4.0. Studies in Big Data, vol 64. Springer, Cham (Springer Book Series) (Invited by Editor in Chief) DOI: https://doi.org/10.1007/978-3-030-25778-1_7

Publications for the year 2018-19

1. Joshi K. N., Patil B. T.(2018), Effect of Illumination Systems on Statistical Texture Parameters based Clustering and Discrimination of Machined Surfaces using Machine Vision, Mapan, Journal of Metrology Society of India pp 1-9 (by Springer Publications) (Scopus Indexed) DOI: https://doi.org/10.1007/s12647-018-0279-z

2. Joshi K. N., Patil B. T., A Review of Machine Vision based Evaluation of Surface Roughness using Texture Analysis Techniques, Industrial Engineering Journal, Nov 2018, pp 22-27 (UGC Approved Journal as per UGC-Care List)

3. Singh S., Deepika,Patil B.T.(2019) Advancements in Design And Fabrication of Conformal Cooling Channels for Improvement in Plastic Injection Molding Process, Industrial Engineering Journal (2019), Volume 12 (5), doi: https://doi.org/10.26488/IEJ.12.5.1171 (UGC Approved Journal as per UGCCare List)

4. Veera Bhadra Rao, M., Shaikh, V. A., and Patil, B, T., (2018), Recent Trends in the Effective Utilization of Minimum Quantity Lubrication (MQL) in Turning Low Carbon Steels. Industrial Engineering Journal. Vol. 11 No. 2, pp. 29-33. ISSN: 2581- 4915 doi: https://doi.org/10.26488/IEJ.11.2.1042 (UGC Approved Journal as per UGC-Care List)

5. Bhise, Dipali., Patil, B, T., and Shaikh, V. A., (2019), Micro lubrication: A way to enhance the machining operation, Industrial Engineering Journal. Vol. 12 No. 4, ISSN: 2581-4915. doi: https://doi.org/10.26488/IEJ.12.4.1169 (UGC Approved Journal as per UGC-Care List)

6. Joshi, K.N. and Patil, B.T., (2019). A Perspective of Integrated Machine Vision Based-Multivariate Statistical Process Control. In Proceedings of International Conference on Intelligent Manufacturing and Automation (pp. 463-471). Springer, Singapore. doi: https://doi.org/10.1007/978-981-13-2490-1_42 (Springer Publications) (Scopus Indexed)

7. Joshi K., Patil B.T (2020) Evaluation of Surface Roughness by Machine Vision Using Neural Networks Approach. In: Parwani A., Ramkumar P. (eds) Recent Advances in Mechanical Infrastructure. Lecture Notes in Intelligent Transportation and Infrastructure. Springer, Singapore doi: https://doi.org/10.1007/978-981- 329971-9_3

8. Joshi K. N., Patil B. T., Recent Developments in Quality Inspection of Spur Gears using Machine Vision Technology, International Conference on Role of Industrial Engineering in Industry 4.0 Paradigm, organized by IIIE, Bhubaneshwar in association with SOA, (ICIEIND– 2018) (Received Best Paper Award)

9. Joshi K.N., Patil B. T., (2018) Machine Vision based Multivariate Statistical Process Monitoring: An Efficient Tool for Quality Control and Management, 3rd National Conference on Industrial Engineering and Technology Management, NCIETM 2018, NITIE (Further published in Udyog Pragati) (Received Best Paper Award)

10. VeeraBhadraRao M., Patil B.T., Shaikh V.A., Sudhakar D.S.S. (2020) Experimental Performance Evaluation of Mist Cooling Using Biodegradable Coconut Oil in Turning of EN24 Steel in Minimization of Tool Wear, Surface Roughness, and Chip Thickness. In: Parwani A., Ramkumar P. (eds) Recent Advances in Mechanical Infrastructure. Lecture Notes in Intelligent Transportation and Infrastructure. Springer, Singapore doi: https://doi.org/10.1007/978-981-32-99719_1

11. Rao M.V.B., Patil B. T., Shaikh V,Jaware R.., Benefits of Using Nano-fluids in Minimum Quantity Lubrication (MQL)Turning of Steel, International Conference on Role of Industrial Engineering in Industry 4.0 Paradigm, organized by IIIE, Bhubaneshwar in association with SOA, (ICIEIND– 2018)

12. Rao M.V.B., Patil B. T., Shaikh V, Sustainability in Plastic World, Proceedings of the NCIHVPE2018, National Conference on “Integrating Human Values in Professional Education”, 12 th -13 th June, 2018, MGM’s College of Engineering & Technology, Kamothe, Navi Mumbai-410209

13. Singraur D.S., Patil B.T., Rampariya Y.T. (2020) Finite Element Analysis of Conformal Cooling for Reduction of Cycle Time to Enhance Performance in Plastic Injection Molding Process. In: Parwani A., Ramkumar P. (eds) Recent Advances in Mechanical Infrastructure. Lecture Notes in Intelligent Transportation and Infrastructure. Springer, Singapore doi: https://doi.org/10.1007/978-981-32-99719_26

14. Deepika Singh Singraour, Dr. Bhushan T. Patil, Yogesh Rampariya, Advancements in Thermoplastic Injection Molding System with Conformally Cooled Channels, International Conference on Role of Industrial Engineering in Industry 4.0 Paradigm, organized by IIIE, Bhubaneshwar in association with SOA, (ICIEIND– 2018)

15. Bhise D..K., Patil B. T., Shaikh V,., A Review of Micro Lubrication for Metal Working Process, International Conference on Role of Industrial Engineering in Industry 4.0 Paradigm, organized by IIIE, Bhubaneshwar in association with SOA, ICIEIND– 2018

16. Kamble Neeraj B., Rane A.B., Korgaonkar S., “Material study for designing portable helmet”, IJRET, June 2018, Vol. 07, Issue 05. DOI 10.15623 / IJRET. I.F. 3.935.

17. Mohite, R., Shaikh, V. A., (2019) “Analysing the effect of Minimum Quantity Lubrication (MQL) on Cutting Tool Wear during Turning using a Novel Two Nozzle Technique”, International Conference on Recent Trends in Mechanical Engineering (ICRTME-2019), January 2019, organized by A. P. Shah Institute of Technology under ICASTe-2019 “The Prism of Conferences”.

18. Sharma S., Singraur D. S., Sudhakar D. S.S., “Transient analysis of an injection mound with conformal cooling channels”, International Conference on Recent Advances in Mechanical Infrastructure (ICRAM-2019), (Accepted for presentation and publication in Lecture Notes in Intelligent Transportation and Infrastructure by Springer publications)

19. Rane, A. B., Sunnapwar, V. K., Sharma, M. R., & Jorapur, V. (2019). Development And Optimization Of Vehicle Assembly Line: A Literature Review. Journal Of Basic And Applied Research International, 38-52.

20. M. V. B. Rao, Bhushan Patil, Vasim Shaikh (2019) Comparative Evaluation of tool Wear, Chip Study and Machined Roughness characteristics in Turning of EN24 Steel in Dry condition, Water flooded and Bio Degradable Coconut Oil based Mist Cooling system at constant machining conditions, NCIETM, NITIE

21. M. V. B. Rao, Dr. Bhushan Patil (2018), Advances in Cyberphysical production system in Industry 4.0, International Conference on Role of Industrial Engineering in Industry 4.0 Paradigm

Publications for the year 2017-18

1. Rao M.V.B., Patil B. T., Recent Trends in the Effective Utilization Of Minimum Quantity Lubrication (MQL) in Turning Low Carbon Steels, Industrial Engineering Journal, Feb 2018, Vol.XI, Issue No-2(pp 29-33), ISSN 0970-2555 (PRINT)

2. Dipali K Bhise, Bhushan T. Patil, Vasim A Shaikh., A Review of Semisolid Casting , International Conference on Manufacturing and Industrial Engineering – 2017 (ICMIE-2017), September 2017 Organized by Indian Institution of Industrial Engineering.

3. Rane A.B., Sakib, “Using GRBL Arduino based controller to run a 2 axis CNC machine”, Int. conf. on Smart City & Emerging technologies (ICSCET), Presented on 5-1-2018 at Universal COE, Vasai (E), Published in proceedings.

4. Rane A.B., Sakib, “Development of 3 axis CNC milling with an open source controller”, Vol.6, Issue 8, Aug 2017. DOI 10.15623 / IJRET. I.F. 3.935

5. Rane A.B., Sonawane A., “Elimination of proprietory control for 3 axis CNC milling machine”, IJRET, Aug.2017, Vol. 06, Issue 08, eISSN :2319-1169 pISSN : 2321-7308.

6. Rane A.B., Sunnapwar V.K., “Assembly line performance and modeling”, Journal of Industrial Engineering International, Vol.13, 2017, Issue no.3, pp.347-355., DOI 10.1007/s40092-017-0189-7, Springer, Original research Published online: 02 March 2017.

7. Rane A.B., Sunnapwar V.K., “Cost models for improved vehicle assembly line performance” Int. J. of Simulation and Process modelling, Vol. 12, Issue no. 2, 2017, pp 111-123, Inderscience publishers.

8. AtiqKudalkar, Sunil Kumar Das,Green Supply Chain Management: A step towards clean and green future, International Journal of Innovative Research in Science, Engineering and Technology, April 2017, Vol. 6, No- 4(pp 1111-1127) ISSN (Online): 2319-8753 ISSN (Print): 2347-6710, DOI:10.15680/IJIRSET.2017.0604001

9. Sunil Das,R. L. Shrivastava, Evaluation of Factors and Performance Measures: Service Quality of Hospital, International Journal of Creative Research Thoughts, 2017, Vol. 5, No. 4 (pp 2250 – 2254) ISSN: 2320-2882

10. Sunil Das, R. L. Shrivastava, Evaluation of Performance Measure Factors for Indian Healthcare Industry, International journal of Engineering Technologies and Management Research, Vol.4 (Iss11): November, 2017 ISSN: 2454-1907 DOI: 10.5281/zenodo.1117169

11. Sunil Das, R. L. Shrivastava, Identification of Success Factors and Performance Measures in healthcare, International Journal of Innovation in Engineering Research & Management, Volume :04 Issue 06 ISSN 2348-4918

Publications for the year 2016-17

1. Vasim A shaikh et al.”Microlubrication machining of 1018 steel:the effect of a biodegradable lubrication on the microstructural integrity”Lubrication science,2017,Wiley online library DOI:10.1002/Is 1373 (Web of Science)

2. Joshi K.N.,Patil B.T., (2016), “Review of Industrial Metrology using Machine Vision.”; International Journal of Emerging Technology and Advanced Engineering, ISSN:2250-2459,Vol.6,No6,pp 125-131

3. Deepika Singh Singraur & Bhushan Patil, “Review on Performance Enhancement of Plastic Injection Molding using Conformal Cooling Channels”, International Journal of Engineering Research and General Science, July-August, 2016 ISSN 2091-2730, Volume 4, Issue 4, July-August, 2016 (PP.176-180)

4. Narkhede, B.E., Mahajan, S.K., Patil, B.T. and Raut, R.D., 2016. Evaluating Factors Influencing Information Quality in Large Firms. , International Journal of Social, Behavioral, Educational, Economic, Business and Industrial Engineering,Vol.11,No.1 pp 30-37

5. Heeranand B. Vhangade , Bhushan T. Patil, Jaladhi Desai , Saurabh Baranwal (2017), “Design for Manufacturing Integration Ontologies and Analysis in Computer Aided Designing,”International Journal of Innovative Research in Science, Engineering and Technology, Vol.6,Issue 6,pp 11773-11779

6. Onkar V Potadar, Bhushan T Patil,(2016). “Development of Gear Measuring Model for Geometrical Measurement of Spur Gears”, Proceedings of First Int. Con. on Materials, Manufacturing and Design Engineering (iCMMD 2016),pp473-477

7. Tejashri Kulkarni,Ramchandra Anvekar,Kiran Wagale, Bhushan T Patil,(2016). “Change Management using OSS:Case Study of Job shop”, Proceedings of Int. Con. on Advanced and Agile Manufacturing nand Agile Software Development(ICAM-ASD2016),pp293-303.

8. Vedavyasrao S. Jorapur et al.”A Promising Initial Population base genetic algorithms for job shop scheduling problem”Journal Of Software Enginering and application,ISSN Print 1945-3116,ISSN Online 1945-3124..

9. Arun Bhiva Rane et al., “Optimization of Vehicle Assembly Line”, 10th ISDSI International Conference, Nasik.

10. Arun Bhiva Rane et al., “Vendor selection by TOPSIS and Pugh Matrix-A case study” in National Convention of Indian Institute of Industrial Engineers, Nagpur, 2016/10.

11. D.S.S.Sudhakar “Automated storage system for kayak” International Research Journal of Engineering and Technology(IRJET):, Volume: 04 Issue: 04, pp 2436-2439,e ISSN: 23950056,April 2017.

12. D.S.S. Sudhakar “Vector Field Based Conversion of Color Image to Gray Scale” International Journal of Advanced Research in Computer and Communication Engineering,:2007 Certified Vol. 5, pp 159-161. Issue .10,October 2016

13. Sakib Shaukat Sarguroh,Arun B Rane, Saurabh A Korgaonkar,D S S Sudhakar “Elimination of proprietary control for computerized numerical control (CNC)machine” Journal of Basic and Applied Research International, Journal of Basic and Applied Research International

Publications for the year 2015-16

1. Shinde R.A., Patil B.T.,Joshi K.N., “Optimization of Tube Hydroforming Process (without Axial feed)by using FEA Simulations”,3rd International Conference on Innovations in Automation and Mechatronics Engineering,ICIAME 2016 organized by G H Patel College of Engineering & Technology, VallabhVidyanagar 388120, Gujarat-India (Published in Elsevier Procedia Technology)

2. Prashant Jadhav ,A.B.Rane ,D.S.S.Sudhakar “Analysis of Burner for Biogas By Computational Fluid Dynamics and Optimization of Design by Genetic Algorithm” at the ‘4th International conferences on Advances in Computer, Communication, and Control, ‘03-04 ICAC4’ 15.

3. A.B.Rane ,Dr. V.K.Sunnapwar ,Dr. S.B.Rane “Strategies to overcome the HR barriers in successful lean implementation” Int. J. of Procurement Management, Published Inderscience publishers,Jan 2015.

4. A.B.Rane, Dr. V.K.Sunnapwar , D.S.S.Sudhakar” Regression modeling for performance improvement of Assembly line” Journal of Basic and applied research international”, Published, International Knowledge Press, May 2015

5. A.B.Rane , Dr. V.K.Sunnapwar , Dr. S.M.Khot, Dr. Ramesh Vulavala “Mathematical modeling of Vehicle assembly line Int. J. of Simulation and Process modelling, Inderscience publishers”,Deceber 2015.

6. A.B.Rane , Dr. V.K.Sunnapwar Dr. S.M.Khot,”Importance of VSM in Lean mfg : A case study Int. conf. “on IE (ICIE 2015) IIIE & ICIE 2015 at SVNIT, Surat , ICIE 2015 – P -177,Published in proceedings ,September 2015.

7. A.B.Rane , Dr. V.K.Sunnapwar , Dr. N. Chari, M.Sharma, V.Jorapur “Improving performance of Lock assembly line using lean and simulation approach International Journal of Business Performance Management (IJBPM)”, Inderscience publishers,Jan 2016.

8. AkshaySarda, Arun.B.Rane,” Simulation of a Vehicle Assembly Line using ARENA “,Int. conf. on IE (ICIE 2015) IIIE & ICIE 2015 at SVNIT, Surat, ICIE2015-P-74 Published in proceedings, Sep 2015.

9. Stephen Joseph K, Ragini Joshi, Pratiksha Gangawane, Sana Kanvinde, D.S.S.Sudhakar”Development of JOLIS GC3000 Gas Cutter Joint Ordinate Linear Interpolation System CNC Machine” Proceedings of the World Congress on Engineering and Computer Science 2015 Vol I October 21-23, 2015, San Francisco, USA.

10. D S S Sudhakar, “Performance Optimization of shell and tube heat exchanger by CFD,International Conferance on emerging trends in Engineering Technology Mumbai 2016.

11. Priya B. Vhangade, D.S.S. Sudhakar, Rajeev A. Solanki, Basappa U. Vhangade “Comparative study of the effect of dwelling the punch at the BDC VS without dwelling at the BDC on the deep drawing process by FE Simulation “IJMET, Volume 7, Issue 3, May –June 2016 , pp.249–266, Article ID: IJMET_07_03_023

12. Shital Dharmul , D.S.S. Sudhakar,”Study of Heating Process in Condenser of Thermokinetic Desorpter ” International Journal of Scientific Engineering and Research,Volume 4,Issue 2,Feb 2016.

13. Vedavyasrao S Jorapur, Vinod S Puranik, Anand S Deshpande, Mahesh Sharma “A promising initial population based genetic algorithm for job shop scheduling problem” Journal of Software Engineering and Applications, Scientific Research Publishing,Volume 9,Pg-208,May 2016.

Publications for the year 2014-15

1. AdityaDarekar, T.S.Venkatesh , BhushanPatil , Yazad Doctor,” Review of optimization aspects for plastic injection molding process”, IRACST- Engg Science & Technology , An International Journal [ESTIJ],1 Feb 2015, ISSN 2250-3498 Vol.5 .

2. Dipali K.Bhise, D.S.S.Sudhakar, HitendraB.Vaishnav,“ Analysis of CH10sm airfoil using computational fluid dynamics”, International conference on Advances in Computer, Communication, and Control 2003-04, ICAC4’15.

3. Hitendra B. Vaishnav, D.S.S.Sudhakar, Dipai k.Bhise, “Effect of Front wing on racing car”, International conference on Advances in Computer, Communication, and Control 2003-04, ICAC4’15.

4. Prasad Kawade, B.S.Ajit Kumar, KashyapAnandpara, D.S.S.Sudhakar, “Computer Aided Design and Analysis of Volatile separating device” ICAC3’15 procedia computer science 00(2014) 000-000.

5. N.Akshayata.C, Aravind Kumar, D.S.S.Sudhakar, “Computer aided process planning in job shop environment”, International conference on Advances in Computer, Communication, and Control 2003-04, ICAC4’15.

6. Jorapur V.S,”Research issues in bottlenecks in discrete manufacturing systems”,IJERT-2012, 2015,Elsevier publications – Computers in Industry vp; 70.

7. Jorapur V.S,”Comparative study different representations in genetic algorithms for job shop scheduling”,Journal of software engineering and applications,2014 ,vol 9.

8. JorapurV.S,”Analysis of discrete manufacturing system of transmission shafts and gears for its optimum performance”.

9. Vijay S. Bilolikar,YogeshGadinaik, “ Simulation based analysis of job shop manufacturing planning”, Annual conference of production and operations management society (POMS), ,May 2015,Washington DC, USA.

10. Vijay S Bilolikar & Karuna Jain , ‘An Adaptive Crossover Genetic Algorithm for Multi-mode RCPSP with Discounted Cash Flows 26th Annual conference of Production and Operations Management Society (POMS), held at Washington DC, USA on May 8th -11th, 2015,.

11. A.B.Rane, “Literature review of development and optimization of vehicle assembly line” ,Open Journal of Optimization (OJOp), ,Nov 2014.,Scientific Research Publishing.

12. A B Rane,“Simulation based case study to improve the performance of an Assembly line” ISDSI International Conference, , January 2015,Pune, India.

13. A B Rane, “Improving the performance of assembly line: Review with case study” International conference on Nascent Technologies in the Engineering Field,2015.

14. A B Rane,“Regression modeling for performance improvement of Assembly line” International conference on Advances in Computer, Communication, and Control 2003-04, ICAC4’15.

15. A B Rane, “Analysis of burner for biogas by computational fluid dynamics and optimization of design by GA” International conference on Advances in Computer, Communication, and Control 2003-04, ICAC4’15.

16. A B Rane, “DES based lean manufacturing implementation in bearing industry” at National conference on Industrial Engg. and Tech. Management, NCIETM-2014, October , 2014.

17. A B Rane,“Strategies to overcome the HR barriers in successful lean implementation” International journal of Procurement Management, Inderscience Publishers, April 2015.

18. A B Rane, “ Simulation of manufactuirng systems” at International conference on eco-friendly Technology for sustainable growth ICEFT-2014,, March 2014, pp 41-46.

19. M.VeeraBhadraRao,“ Low cost Automation”, LalaLajpathrai Institute of Management Studies , March 2015,Mahalaxmi.

20. Manoj J. Ghag,M.VeeraBhadraRao, “Review of optimization techniques such as DOE and GRA used for process parameters of Resistance spot welding”, (IJSR) ISSN:2319-7064, Volume 4, 6, June 2015, Paper ID:SUB155288, pp 701-705.

21. Manoj J. Ghag, M.VeeraBhadraRao, “Optimization of process parameters in resistance spot welding of IS410:2006 grade CuZn40 brass material using Taguchi method”, (IJSER) ISSN:2347-3878, Volume 3, Issue 6, June 2015, Paper ID:IJSER15273, pp 92-97.

22. Imran A. Shaikhand, M.VeeraBhadraRao, “A Review on Optimization process parameters for TIG welding using Taguchi method & Grey Relational Analysis”, (IJSR) ISSN:2319-7064, Volume 4, 6, June 2015, Paper ID:SUB155855, pp 2449-2452.

Innovative Teaching and Learning Practices

- Measure the physical dimensions of the component,

- Prepare a complete working drawing with front, top, side, and sectional views, as well as an isometric view,

- Collaborate effectively within their team to complete the task, and

- Present their work to the class, explaining their approach and technical drawing.

This activity aimed to foster teamwork, improve technical drawing skills, and bridge the gap between theory and real-world application through experiential learning.

| 2024-25 | ||||

|---|---|---|---|---|

| Sr. No. | Name of the faculty | Subject | Sem | Activity |

| 1 | Dr. Dipali Bhise | Introduction to CAD | V | Review Research Paper writing |

| 2 | Prof. D S S Sudhakar | Mechatronics | III | Circuit Demonstration |

| 3 | Prof. Saurabh Korgaonkar | Engineering Graphics | I | 3d Modelling software used in Aiding the visualization |

| 4 | Prof. Saurabh Korgaonkar | Automation and Artificial Intelligence | VII | 3d Modelling software used in Aiding the visualization |

| 5 | Prof. Aseem Nevrekar | Report Writing | ALL | Report Writing using Latex software |

| 2023-24 | ||||

| Sr. No. | Name of the faculty | Subject | Sem | Activity |

| 1 | Prof Saurabh Korgaonkar | Mechanical measurement and control | V | MATLAB session on Steady state and time response |

| 2 | Dr Ketki Joshi | DOM/Machine Design | V | Quiz |

| 2022-23 | ||||

| Sr. No. | Name of the faculty | Subject | Sem | Activity |

| 1 | Prof. Akshay Save | Kinematics of Machinery (Flipped classroom method) | IV | Motion analysis and plotting of displacement-time; velocity-time; acceleration-time; jerk-time diagram and layout of cam profile |

| 2 | Prof. Akshay Save | Kinematics of Machinery (Flipped classroom method) | IV | Gear and gear trains |

| 3 | Prof. Akshay Save | Dynamics of Machinery (Flipped classroom method) | V | Working of Governor and Gyroscope |

| 4 | Prof. Akshay Save | Dynamics of Machinery (self-made Experiment Workbook manual) | V | Assignment and Experiment manual |

| 5 | Prof. Deepika Singarur | Dynamics of Machinery (Virtual labs) | V | Working of porter governor |

| 6 | Prof. Deepika Singarur | Thermal Engineering | V | Heat transfer in a double pipe heat exchanger |

| 7 | Dr. Ketaki Joshi | Design of mechanical system (Power point presentation and mini project) | VII | Hoisting equipment, gear box, steering mechanism |

| 8 | Dr. Vasim Shaikh | Materials and Metallurgy (self-made video lectures) | III | Ceramics (types and processing) |

| 9 | Dr. Arun B. Rane | Machinery Diagnostics (virtual labs) | VII | Bearing defects, machining servicing, shaft misalignment simulation |

| 10 | Prof. M V B Rao | Engineering Graphics (self-made Experiment Workbook manual) | II | Past University Question paper |

| 11 | Dr. Bhushan Patil | Engineering Mechanics (Pragmatic learning) | I | 1) Calculate height from 4th floor to 1st floor; 2) Calculate height of the room |

| 12 | Dr. Bhushan Patil | Engineering Mechanics (Debate) | I | Debate topic: Friction is good or bad |

| 13 | Prof Saurabh Korgaonkar | Mechanical measurement and control | V | MATLAB session on Steady state and time response |